Overview

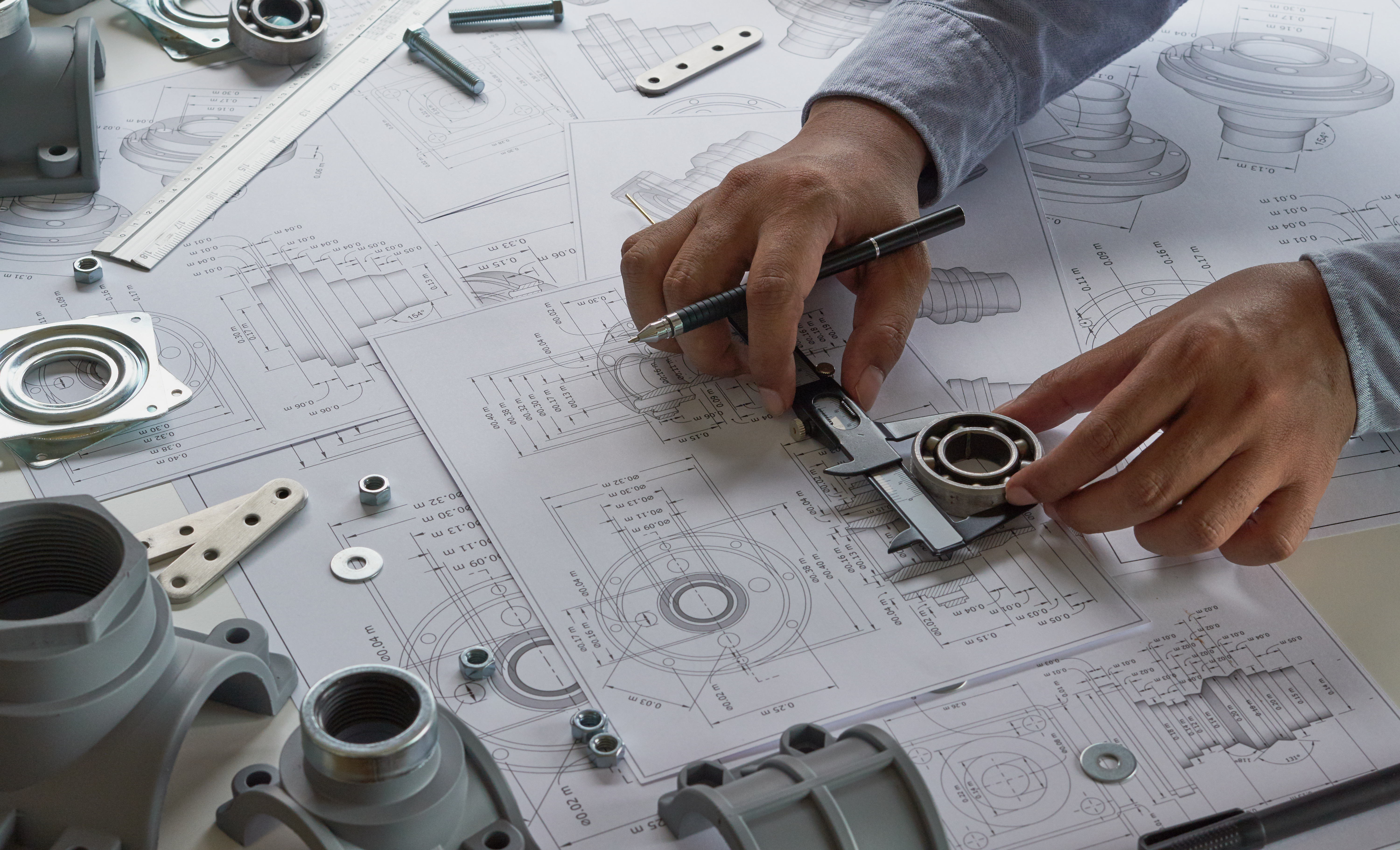

Avtec Finishing Systems and Nico Products development teams work with many OEM Manufacturers to add value to their product line through our wide array of metal finishing options. Whether looking to improve corrosion or wear resistance, enhance part aesthetics, or to make your product stand out in the marketplace, we’ve got options for you. With dozens of finish and plating options, many look to The Lindgren Group as the one-stop shop for their metal finishing needs.

OEM Options

Most OEM components and products demand metal finishing or plating to make them more durable and long-lasting and protect them against wear, heat, corrosion, friction, and the environment. Some specifications also require coatings to enhance electrical conductivity, insulate against conductivity, and otherwise increase performance.

Metal Finishing options from The Lindgren Group used in OEM applications include:

- Anodize and Hardcoat

- Chromate Conversion

- Zinc and Zinc Nickel

- Electrolytic Nickel Plating

- Electroless Nickel

- Gold and Silver Plating

- Tin Plating

- More…

Some of our clients include Cirrus Design, Parker Hannifin, Caterpillar, and John Deere.

The Lindgren Group: Avtec Finishing Systems and Nico Products work with many OEM manufacturing companies to provide superior-quality metal finishing and plating options for numerous applications. Work with our R&D, Quality, and Production teams to determine the specifications you need for any project.