Black Oxide

Black Oxide is an inexpensive conversion coating that does not chip, flake, or create dimensional changes and can be welded. Adding an oil or topcoat adds corrosion resistance to the oxide coating.

Bright Dip

Bright dip enhances the brightness of base metals like copper and brass for a shiny finish and clean surface.

Chromate Conversion

Chemical conversion coatings are applied to aluminum and zinc substrates to slow corrosion and are great for paint adhesion and low electrical resistance. Our RoHS-compliant conversion coatings are used in many industry applications.

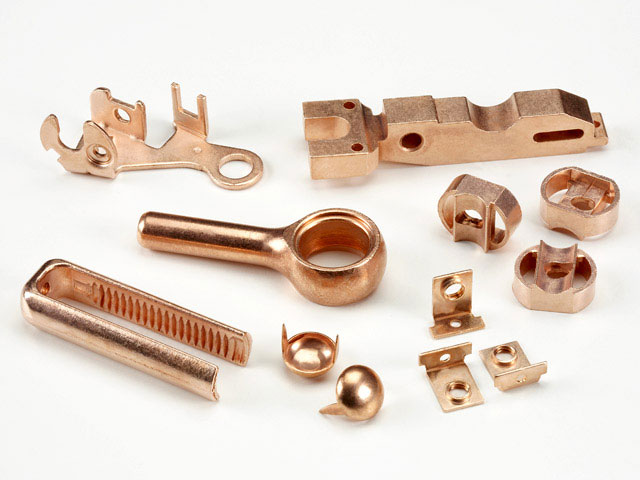

Copper

Copper plating is typically applied to steel, zinc, aluminum, or stainless steel to produce smooth, conductive finishes and create an excellent diffusion barrier.

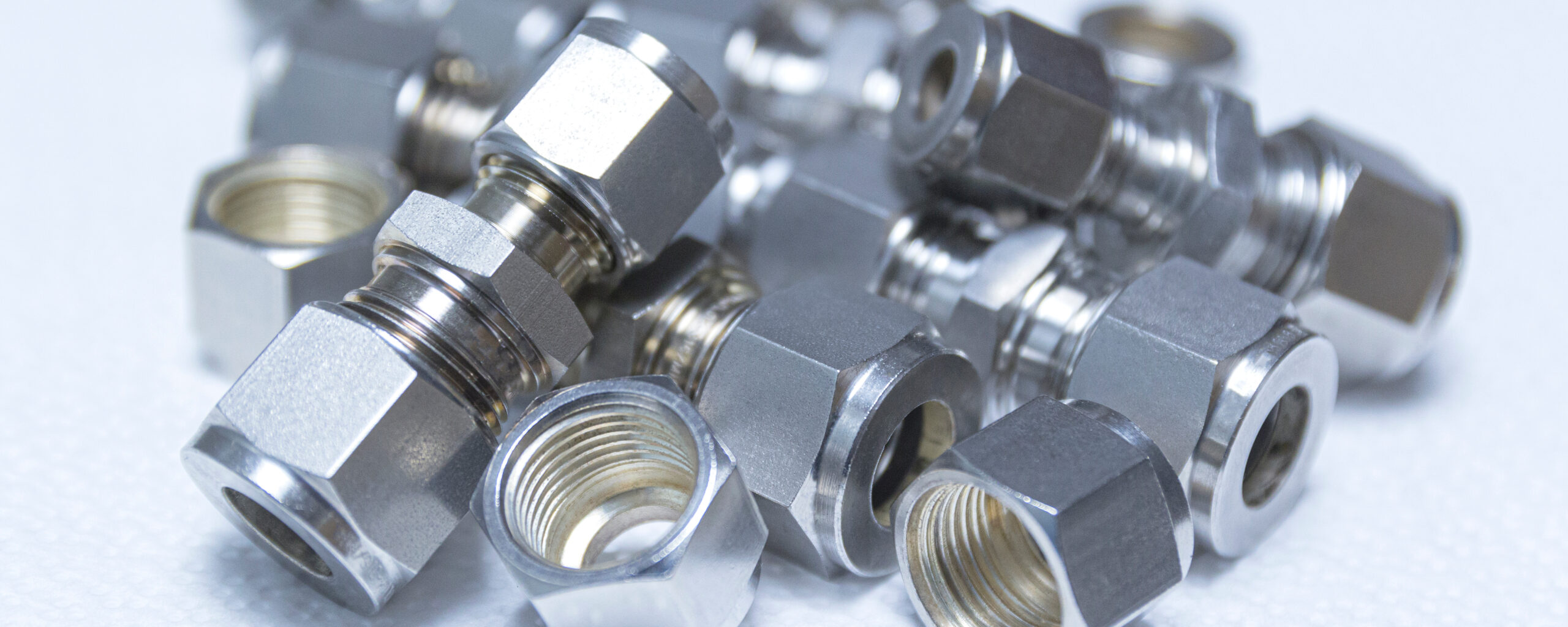

Electroless Nickel

Electroless Nickel Plating uses chemical processes to plate nickel onto steel, aluminum, brass, stainless steel, and zinc die-cast for corrosion and wear protection, solderability, and lubricity. Its unique properties allow us to engineer this coating to function in many applications.

Electroless Nickel Boron

Electroless Nickel Boron is a popular coating chemically applied to uniformly coat complex shapes. It increases hardness, heat, and wear resistance while providing lubricity to reduce abrasion.

Electrolytic Nickel

Nickel electroplating uses an electrolyte solution and an electrical current to apply nickel coating on steel, stainless steel, aluminum, and zinc die-cast materials for a high luster and wear resistance.

Electropolish on Stainless Steel

Electropolishing is an electrochemical process that removes material from a stainless steel part. It is used to chemically polish and brighten a part, with the added benefit of removing free iron from the surface.

Gold

Gold plating is used in many high-tech industries. Gold Plating is widely used in critical applications throughout many industries and is known for its excellent electrical conductivity, corrosion-inhibiting properties, and ability to increase part durability.

Passivate

Avtec Finishing Systems offers nitric acid passivation, sodium dichromate, and citric acid passivation to remove free iron from the surface of stainless steel and prevent corrosion.

Phosphate

Phosphate coating protects iron and steel components against wear and corrosion and provides a stable base for other coatings, including paint. Nico Products offers both Manganese Phosphate and Zinc Phosphate options to improve your part performance.

Silver

Silver plating provides substrates with superior conductivity and corrosion resistance. It can be soldered and used for bearing surfaces and anti-galling applications.

Tin

Tin plating is commonly used in bus bars and electrical applications. It also resists oxidation, exhibits good conductivity, and is non-toxic and non-carcinogenic.

Type II Anodize

Type II Anodizing, or Sulfuric Acid Anodizing, uses electrolytic oxidation to create an aluminum oxide surface on an aluminum part for increased wear and corrosion resistance, heat dissipation, and aesthetics.

Type III Hardcoat Anodize

Type III Anodizing, also known as Hardcoat Anodize or Hard Anodizing, creates a thicker and more durable layer than Type II Anodizing. Hardcoat is corrosion resistant and non-conductive. With wear properties similar to a part with a Rockwell Hardness over 60, it is a very durable coating option for aluminum.

Value Added Services

Both Avtec Finishing and Nico Products offer numerous value-added services, including dry film lubricants, blasting, tumbling, masking, baking, and more.

Vapor Degrease

Solvent vapor degreasing is a popular parts-cleaning process for removing contaminants on materials in the medical, electronics, aerospace, and communications industries. Removing contaminants, oil, and debris from parts provides clean surface conditions for successfully plating your parts.

Zinc

Zinc plating is a form of cathodic protection used to combat corrosion, primarily steel. It is used in many applications. Available chromates and topcoats enhance aesthetics and corrosion resistance.

Zinc Nickel

Electroplated Zinc-nickel offers excellent corrosion protection when applied over ferrous substrates. It is popular in automotive, agricultural, and other durable goods industries. With corrosion resistance exceeding 1000 hours in some cases, Zinc Nickel is seeing significant growth in the industry.