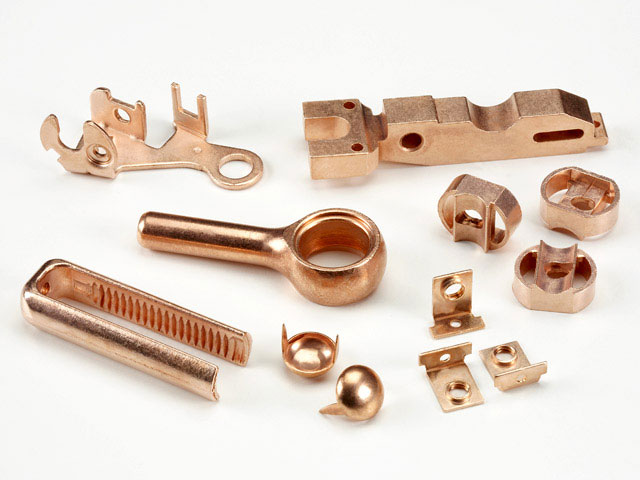

Overview

Copper plating creates an outstanding barrier layer covering substrate metals and alloys. Utilizing copper plating provides an easy-to-plate, level, and, in some cases, smooth substrate, making it even more popular than nickel plating for specific metal finishing applications. Although it can be used independently, copper is typically used as an underplate for nickel, tin, gold, or silver deposits.

Copper plating provides an excellent diffusion barrier, preventing components of the base material from migrating into the subsequent plating layers. Copper plating generates high electrical conductivity, making it a wonderful and inexpensive choice for high-tech products and other applications.

Features & Benefits of Copper Plating Options and Specifications of Copper Plating:

- Excellent Diffusion Barrier

- High Electrical Conductivity

- Excellent Underplate

- EMI Shielding in Electronic Circuitry

- Can help provide a level and smooth substrate for plating

- Can be applied to Steels, Zinc Die Cast, Aluminum and Aluminum Die Cast, Stainless Steel

Specifications

AMS-2418

MIL-C-14550 (Superceeded by AMS-2418)

ASTM B734

Request a Quote

How can Lindgren Group’s Avtec Finishing Systems and Nico Products Divisions partner with your company for greater success? Between our two facilities, we offer dozens of chemical and electroplating options, Gold Plating and other precious metal plating options, mechanical finishes, and quality systems to support our efforts in providing you with the best Metal Finishing available in the market today. Complete the form below to request a quote.