Overview

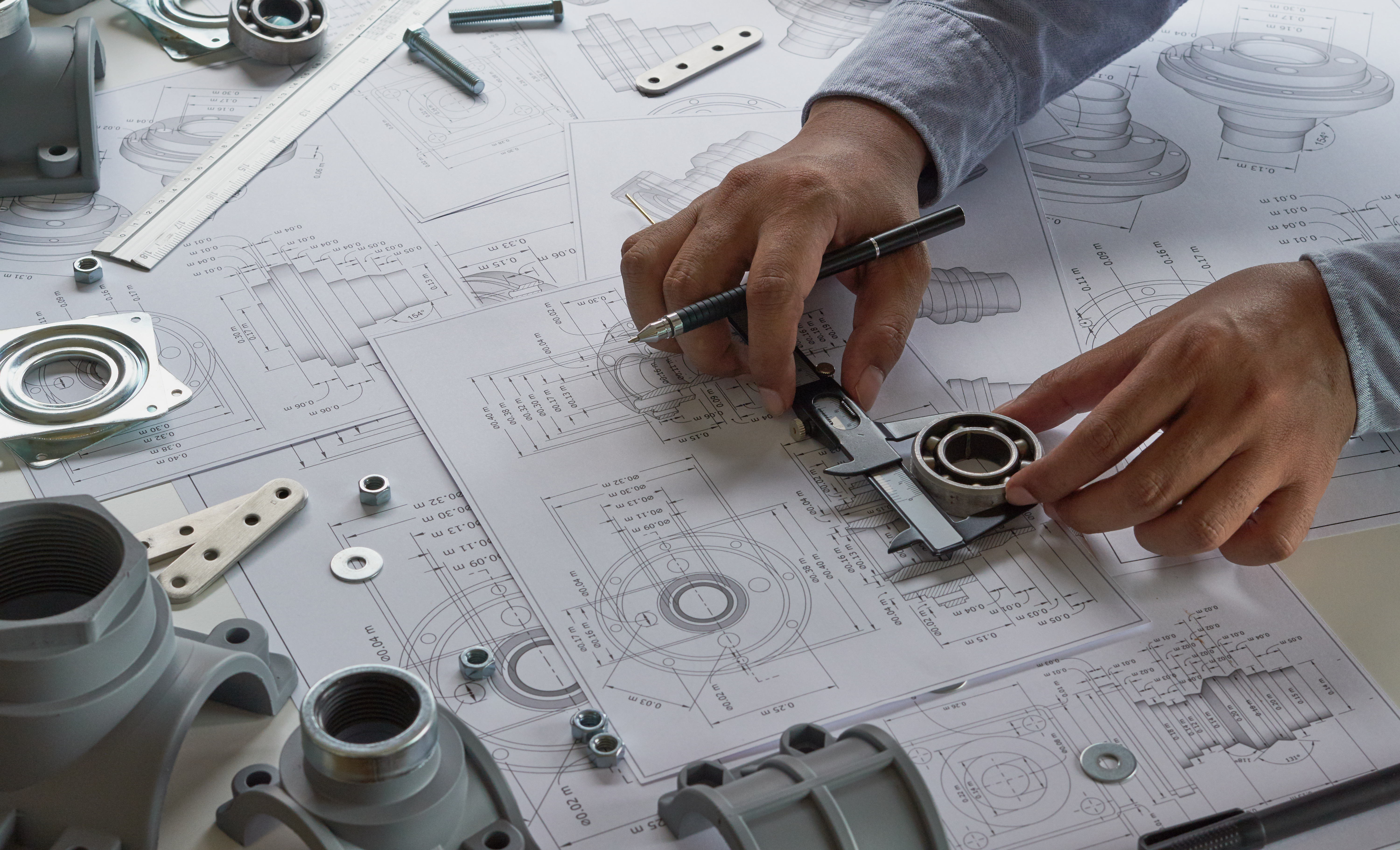

Electroless Nickel Plating is the deposition of a nickel-phosphorous alloy onto a metal substrate without using an electrical current. The electroless nickel plating process utilizes an autocatalytic chemical reaction to deposit a reliable, repeatable coating of uniform thickness. This uniformity of deposit eliminates the need for post-plate grinding. Electroless nickel demonstrates excellent corrosion protection, solderability, and lubricity. Electroless nickel effectively coats parts with sharp edges, deep recesses, seams, threads, and complex geometries.

Applications and Specifications of Electroless Nickel

Our superior-quality Electroless Nickel plating from Avtec Finishing Systems is commonly used on:

- Automotive components

- Aerospace Components

- Electrical Equipment

- Molds and Dies

- Food service equipment

- Gas and oil components

- Printing industry equipment

- Salvage

- Packaging and handling machinery

These Electroless Nickel finishing options are available:

- Medium Phosphorous – Best for appearance.

- High Phosphorous – Superior corrosion protection, most resistant to acidic environments.

- High Build, exceeding .0007

- Nickel Teflon – Increased lubricity and low reflectivity. It can reduce or eliminate the need for liquid lubricants.

- Nickel Boron – for applications requiring advanced wear and lubricity.

Common Specifications:

- AMS 2404

- MIL-C-26074 and MIL-C-26074E are superseded by AMS2404

- AMS 2454

Electroless Nickel is commonly used on these substrates:

- Steel

- Aluminum

- Brass

- Stainless Steel

- Zinc Die Cast

- Hardened Alloys

Request a Quote

How can Lindgren Group’s Avtec Finishing Systems and Nico Products Divisions partner with your company for greater success? Between our two facilities, we offer dozens of chemical and electroplating options, Gold Plating and other precious metal plating options, mechanical finishes, and quality systems to support our efforts in providing you with the best Metal Finishing available in the market today. Complete the form below to request a quote.