Overview

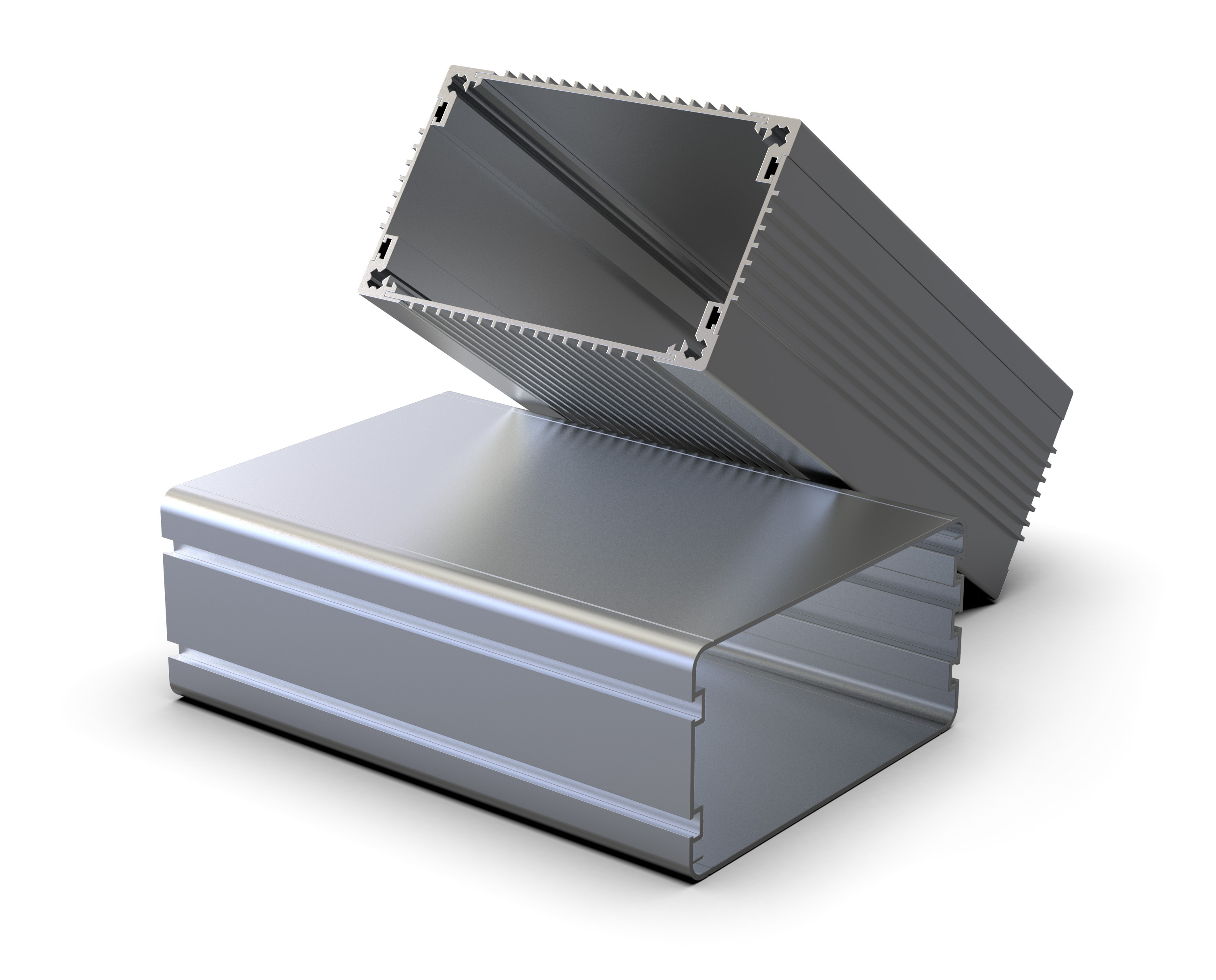

Type II Anodizing, also known as Sulfuric Acid Anodizing, uses electrolytic oxidation to create an aluminum oxide surface on an aluminum part. This oxide layer combines buildup on the part’s surface and penetration into the aluminum. The typical ratio of penetration vs. buildup is 70 penetration/30 buildup. The finish gives the part better wear and corrosion resistance and a surface that can be easily colored to fit the application.

Features & Benefits of Type II Anodize

- Increased wear resistance

- Increased corrosion resistance (up to 336 hours of salt spray on a panel)

- Electrical insulation

- Enhanced appearance through the use of colored dyes

- Better paint adhesion

- Enhanced heat dissipation

Typical Industries:

- Medical

- Automotive

- Aftermarket commercial

- Aerospace

- Sporting Goods

- Firearms

- Recreational Products

Specifications:

MIL-A-8625

MIL-PRF-8625

AMS-A-8625

ASTM B580

Request a Quote

How can Lindgren Group’s Avtec Finishing Systems and Nico Products Divisions partner with your company for greater success? Between our two facilities, we offer dozens of chemical and electroplating options, Gold Plating and other precious metal plating options, mechanical finishes, and quality systems to support our efforts in providing you with the best Metal Finishing available in the market today. Complete the form below to request a quote.