Overview

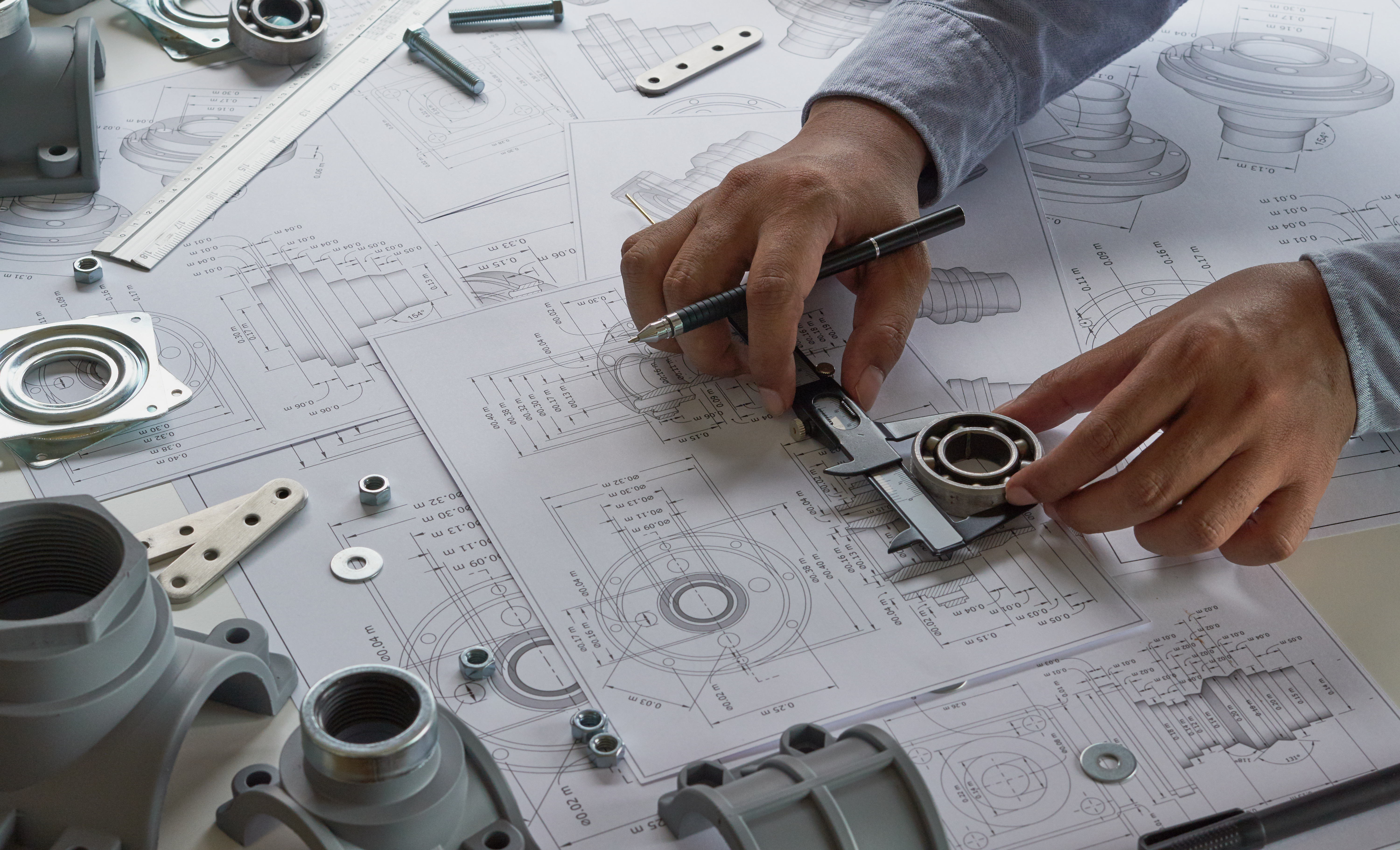

Type III Anodizing, also known as Hardcoat Anodizing or Hard Anodize, is similar to Type II Anodizing but creates a thicker, more durable layer of aluminum oxide on the surface of the finished part. This is accomplished by manipulating the current density and bath parameters. After this process, the resulting finish has superior wear and corrosion resistance.

As with Type II Anodizing, the finish is integral to the part as it penetrates the part and builds up on the surface. Due to its extreme hardness, machining after hardcoat is very difficult. Often, threaded holes are masked or plugged during the process if not machined to accept hardcoat buildup.

Applications and Specifications of Type III Hardcoat Anodize

- Machinery, for its wear resistance, especially with high-speed machine parts

- Electronics, since it provides constant emissivity

- Marine, for its corrosion resistance, especially with salt-water

- Oil, for its excellent corrosion and wear resistance

- Air and Space, for durability, longevity, and lightweight characteristics

- Cookware, for corrosion protection and non-stick properties

- Automotive

- Firearms

- Recreational

- Sporting Goods

Specifications:

MIL–A-8625

MIL-PRF-8625

AMS 2469

AMS-A-8625

ASTM B580

Request a Quote

How can Lindgren Group’s Avtec Finishing Systems and Nico Products Divisions partner with your company for greater success? Between our two facilities, we offer dozens of chemical and electroplating options, Gold Plating and other precious metal plating options, mechanical finishes, and quality systems to support our efforts in providing you with the best Metal Finishing available in the market today. Complete the form below to request a quote.