Nico Finishes

In addition to the finishes noted below, The Lindgren Group is always willing to consider new finishes and/or specifications to meet our customers needs. Please reach out to us to discuss your project.

Bright Dip

Bright dip enhances the brightness of base metals like copper and brass for a shiny finish and clean surface.

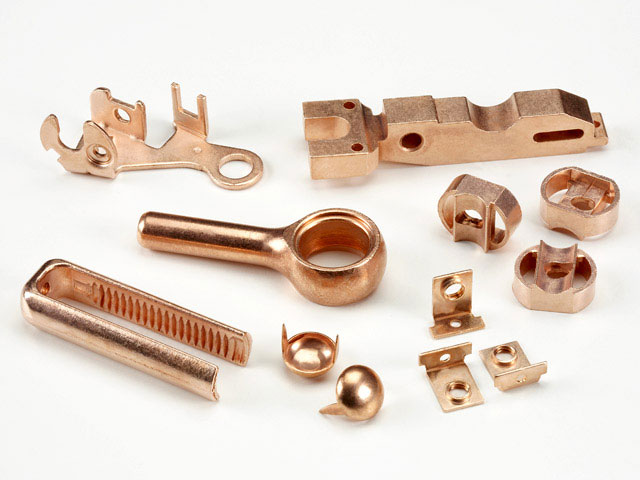

Copper

Copper plating is typically applied to steel, zinc, aluminum, or stainless steel to produce smooth, conductive finishes and create an excellent diffusion barrier.

Electrolytic Nickel

Nickel electroplating uses an electrolyte solution and an electrical current to apply nickel coating on steel, stainless steel, aluminum, and zinc die-cast materials for a high luster and wear resistance.

Gold

Gold plating is used in many high-tech industries. Gold Plating is widely used in critical applications throughout many industries and is known for its excellent electrical conductivity, corrosion-inhibiting properties, and ability to increase part durability.

Phosphate

Phosphate coating protects iron and steel components against wear and corrosion and provides a stable base for other coatings, including paint. Nico Products offers both Manganese Phosphate and Zinc Phosphate options to improve your part performance.

Silver

Silver plating provides substrates with superior conductivity and corrosion resistance. It can be soldered and used for bearing surfaces and anti-galling applications.

Tin

Tin plating is commonly used in bus bars and electrical applications. It also resists oxidation, exhibits good conductivity, and is non-toxic and non-carcinogenic.

Value Added Services

Both Avtec Finishing and Nico Products offer numerous value-added services, including dry film lubricants, blasting, tumbling, masking, baking, and more.

Vapor Degrease

Solvent vapor degreasing is a popular parts-cleaning process for removing contaminants on materials in the medical, electronics, aerospace, and communications industries. Removing contaminants, oil, and debris from parts provides clean surface conditions for successfully plating your parts.

Zinc

Zinc plating is a form of cathodic protection used to combat corrosion, primarily steel. It is used in many applications. Available chromates and topcoats enhance aesthetics and corrosion resistance.

Zinc Nickel

Electroplated Zinc-nickel offers excellent corrosion protection when applied over ferrous substrates. It is popular in automotive, agricultural, and other durable goods industries. With corrosion resistance exceeding 1000 hours in some cases, Zinc Nickel is seeing significant growth in the industry.